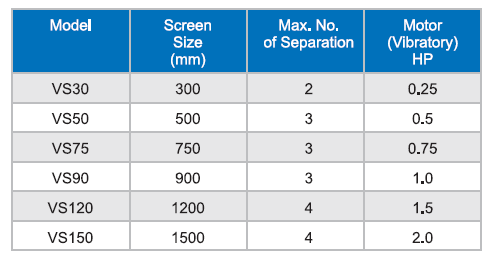

Vibratory Gyro Screen – Efficient Screening, Separation, and Filtration Solutions

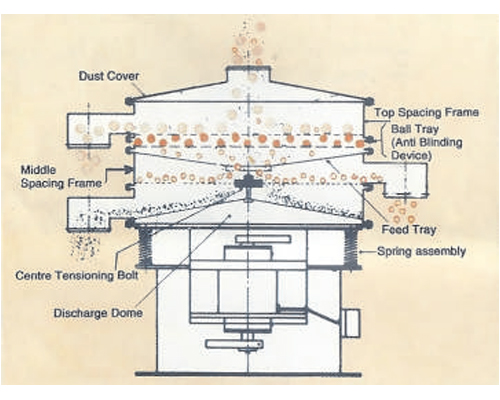

VIBRANT Vibratory Gyro Screens are advanced screening machines designed for effective separation, classification, and filtration of powders, grains, slurry, liquids, and more. Utilizing gyratory vibrations generated by eccentric weights mounted on a motor, these screens ensure precision and efficiency in material processing.

Key Features

- High Precision – Delivers accurate separation, grading, and filtering of materials based on particle size.

- Versatile Design – Suitable for applications across a wide range of industries, including food processing, pharmaceuticals, chemicals, ceramics, and more.

- Multiple Layer Capability – Equipped to handle up to five layers, enabling simultaneous separation of different particle sizes.

- Low Noise Operation – Engineered for quiet functioning, making them ideal for sensitive environments.

- Durability and Efficiency – Built to last, offering reliable performance for demanding industrial applications.

Applications of VIBRANT Vibratory Gyro Screens

- Material Separation and Classification

- Efficiently separates materials based on size and properties, ideal for powders, granules, liquids, and slurry.

- Industry-Specific Applications

- Pharmaceutical Industry

- Food Industry

- Ceramic Industry

- Paint Industry

- Chemical Industry

- Plastic Industry

- Paper Industry

- Rubber Industry

- Abrasive Industry

- And many more

Performance and Capabilities

The VIBRANT Vibratory Gyro Screens operate with gyratory vibrations that create both circular and vertical movement, ensuring efficient material processing. Their multi-layer functionality and high precision make them indispensable for various industrial applications.