Electro Mechanical Vibratory Feeders – Efficient and Durable Material Feeding Solutions

VIBRANT Electromechanical Vibratory Feeders are robustly designed to handle challenging material feeding applications with ease and reliability. By utilizing vibratory motors for excitation, these feeders provide consistent and efficient feeding across various industrial operations.

Key Features

- Vibratory Motor-Driven Excitation – Features a combination of one or two vibrator exciters, selected based on specific application requirements, ensuring optimized performance.

- Rugged Construction – Built for durability, reducing maintenance needs and enhancing operational efficiency even in demanding conditions.

- Variable Feed Rate – Feed rate is influenced by application factors, including:

- Material Density – Adjusts for different material weights.

- Trough Dimensions – Length and width determine feed capacity.

- Hopper Design – Impacts the flow characteristics and performance of the feeder.

Applications of VIBRANT Electromechanical Vibratory Feeders

- Material Feeding and Handling – Consistent feeding of bulk materials across industrial processes.

- Versatile Operations – Suitable for feeding a variety of materials, from fine powders to coarse aggregates.

- Rugged Industrial Use – Effective in handling materials under abrasive or heavy-duty conditions.

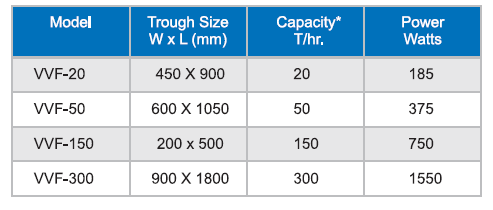

Performance and Capacity

- Feed rate and power specifications vary based on application requirements.

- VPM (Vibrations Per Minute) and motor power are selected to ensure optimal performance for the specific material and process needs. Available in different VPM (3000, 1500, 1000 etc)

The indicative specification table can assist in initial selection, but exact specifications are customized based on individual application requirements