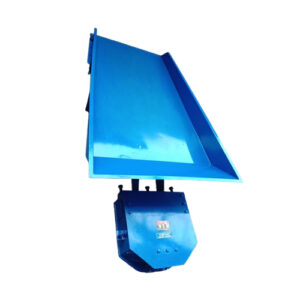

Electromagnetic Vibratory Feeders – Efficient and Controlled Material Feeding Solution

VIBRANT Electromagnetic Vibratory Feeders are designed to deliver precise, consistent, and reliable feeding solutions for industrial applications. With a focus on durability and efficiency, these feeders operate at 3000 VPM and provide volumetric flow control to ensure seamless material handling.

Key Features

- Rugged Electromagnetic Design – Ensures long-term reliability without mechanical components such as gears, cams, or bearings that require maintenance or lubrication.

- Precise Flow Control – Comes equipped with a controller that allows operators to adjust the flow rate of materials effortlessly via a simple knob.

- Versatile Material Handling – Capable of efficiently handling a wide range of materials, including:

- Hot or Abrasive Materials – Suitable for challenging environments.

- Fragile Materials (e.g., potato chips) – Ensures gentle handling without material degradation.

- Smooth and Continuous Operation – Prevents material jamming, ensuring uninterrupted processes.

- Special Operations – Can perform additional functions like magnetic separation, heating, cooling, and drying, offering flexibility for various industrial requirements.

- Enhanced Safety – Designed to minimize safety hazards for personnel working near the feeder.

Applications of VIBRANT Electromagnetic Vibratory Feeders

- Material Feeding and Flow Control

- Accurate and consistent feeding of bulk materials in industrial processes.

- Specialized Material Handling

- Managing delicate materials without causing damage.

- Handling abrasive or high-temperature materials in challenging environments.

- Auxiliary Operations

- Performing magnetic separation, as well as heating, cooling, or drying materials during feeding.

Performance and Capacity

- Operating Speed: 3000 VPM (Vibrations per minute)

- Capacity: Depends on material type and density. For example, the standard capacity chart is based on handling dry sand or coarse material (1600 kg/m³):

- Heavier Materials – Increased capacity.

- Lighter or Finer Materials – Reduced capacity.

SELECTION TABLE