Electromagnetic Vibrators – Precision Vibration Control for Material Handling & Processing

VIBRANT Electromagnetic Vibrators are designed for continuous operation at 3000 VPM, ensuring controlled vibration for various industrial applications. These vibrators enhance material flow, and mainly assist in De-Clogging of material from Hopper, Bin, Chute etc, improving efficiency across multiple industries.

Selection Criteria for Electromagnetic Vibrators

Choosing the right vibrator depends on multiple factors :

- Purpose of Vibration – Whether the requirement is to flow, compact, or settle the material.

- Material Characteristics – Density, particle size, moisture content, and flowability.

- Weight of Material – Determines the intensity of vibration required for effective handling.

- Hopper/Bin Design – Wall thickness, shape, and installation setup influence the selection.

- Number of Vibrators – Based on hopper capacity, multiple units may be required for uniform operation.

The appropriate vibrator size is determined using the general selection chart, ensuring compatibility with hopper dimensions and material characteristics.

Applications of VIBRANT Electromagnetic Vibrators

- Material Flow Enhancement

Vibrating Bins & Hoppers – Ensures steady movement of bulk materials, preventing blockages.

Vibrating Chutes – Regulates the flow of materials for consistent processing. - Separation & Screening

Vibrating Sieves & Screens – Enables the sorting of materials into different sizes at controlled rates. - Compaction & Settling

Vibrating Containers – Increases net weight content by eliminating air pockets.

Material Compaction – Removes blowholes and improves density in packed materials.

SELECTION TABLE

DIMENSIONS FOR ELECTRO MAGNETIC VIBRATORS

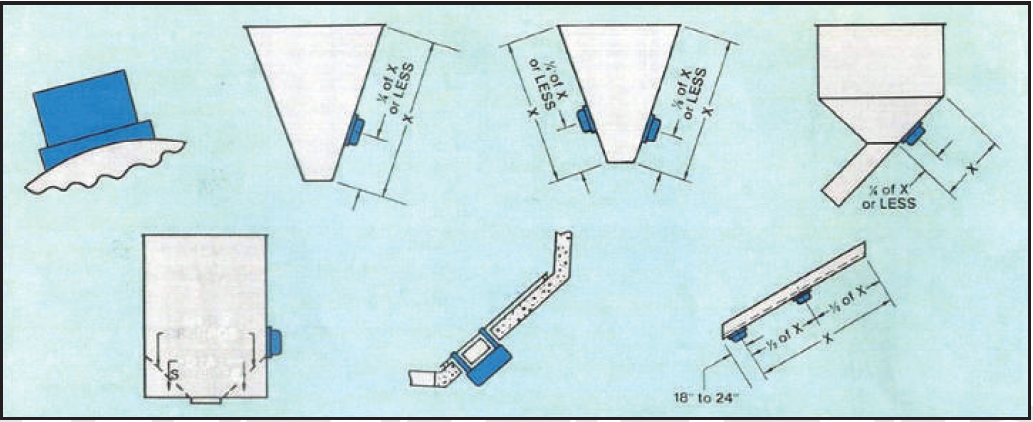

APPLICATION AND MOUTING

The most ideal installation of vibrator is at 1/4 or 1/3 of its slope length of hopper from the discharge. If more than one vibrators are required to be installed on one hopper they should be equally apart and should be connected in the same phase of supply